How a Regenerative Blower Works

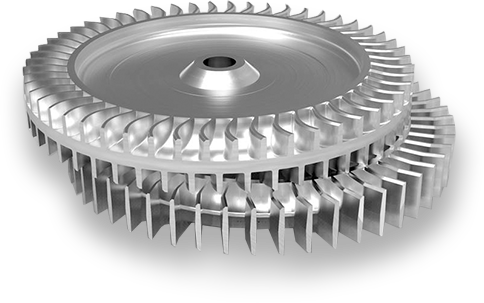

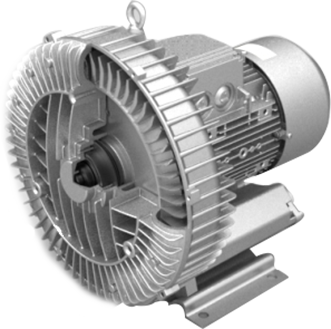

Regenerative Blower, also known as side channel blowers or ring compressor blowers, are dynamic compressors, in which contactless rotating impellers transfer energy to the conveyed medium. The gas to be conveyed is typically pulled in through an integrated silencer and the energy transfer then takes place repeatedly in the impeller stage.

On the pressure side of the side channel, the gas is stripped off at the interceptor point and flows to the pressure-side connection via a second integrated sound absorber. The energy transmission takes place in one stage, or for higher differential pressures in two stages by means of two series-connected impellers.

Parts of a Regenerative Blower

Regenerative Blower Are Used In These Industry Sectors

Regenerative Blower Are Maintenance-Free

- External, permanently lubricated bearings

- Contactless rotating impellers

- Fan-cooled motors

Regenerative Blower Are User-Friendly:

- Weight-optimised design through aluminum pressure casting parts

- Possibility for a vertical or horizontal installation

- Suitability for converter operation

Regenerative Blower Are Environmentally Friendly:

- Oil-free operation

- Contactless rotating impellers

- Fan-cooled motors

Airtech Regenerative Blower Can be Used World-Wide:

50/60Hz voltage range motors of the Iso class FProtection type IP55 with an integrated thermal protection switch (standard) CE, UL and CSA certifications

Your Advantages with Airtech Regenerative Blower:

- A large selection of sizes in stock

- Extensive accessories and spare parts

- 100% checked prior to delivery

- Service in our facilities or on site

- Fast and reliable delivery