Custom Solutions examples

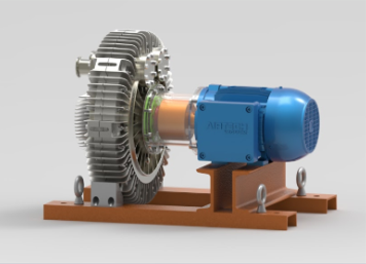

Stainless Steel Blower a With Magnetic Drive

Used in the biogas industry, this blower can withstand harsh gases such as hydrogen sulfide (H2S), while containing up to 100PSIG static pressure.

Features:

- Stainless Steel Blower Construction

- Aluminum Heat Sinks for Maximum Cooling

- Magnetic Drive with Borosilicate Barrier

- Internal Teflon Sealing for Maximum Performance

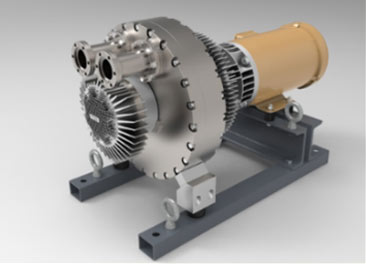

Custom High Speed Centrifugal Compressor

Used in the pneumatic conveying industry, this compressor is ultra high efficient and is smaller & lighter than gas moving technologies of comparable performance.

Features:

- 81% Polytropic Efficiency

- Can be constructed of aluminum, stainless steel, and more

- Custom accelerometer for preventative maintenance

High Temperature Stainles Steel Blower With Magnetic Drive

Used in the defense industry, this blower is designed to maintain gas at 350C (662F), while containing up to 150 PSIG static pressure.

Features:

- Stainless Steel Blower Construction

- Aluminum Heat Sinks for Maximum Cooling

- Magnetic Drive with Borosilicate Barrier

- Internal Teflon Sealing for Maximum Performance

Nickel Coated Blower with Stainless Steel Motor

Used in the food & beverage industry, this blower features nickel coating for corrosion resistance and washdown capabilities

Features:

- High Phosphorus Electroless Nickel Coated Blower

- Stainless Steel Washdown Motor

- Custom Sanitary Flange Connection

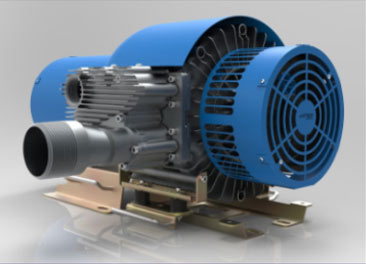

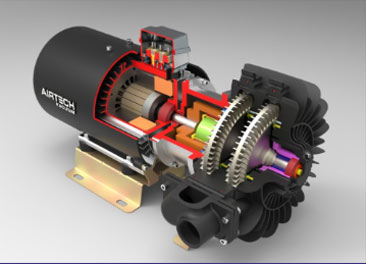

Centrifugal Compressor with Magnetic Drive

Used in high temperature applications, this blower features an integrated accelerometer to measure the health of the bearing.

Features:

- Custom Blower Construction

- Integrated Bearing Vibration Accelerometer

- External AC/DC Fans for maximum Cooling

- Magnetic Drive with Composite Barrier

Stainless Steel Blower With Composite Impeller

Used in the sanitation industry, this blower is made with both stainless steel and composite materials.

Features:

- Stainless Steel Blower Construction

- Composite Impeller for reduced weight

- Robust design to handle high G-forces

- Premium Efficient Motor

Miniature Laboratory Blower

Used in the medical industry, this blower was designed to achieve high pressure in a confined footprint.

Features:

- Custom Aluminum Blower Construction

- Noise Abating Impeller Design

- Hermetically Sealed

Blower with Integrated Variable Frequency Drive & Heat Exchanger

Used in the medical industry, this blower features both and integrated variable frequency drive and heat exchanger for a simple, turnkey solution.

Features:

- Electroless Nickel Coated Blower Construction

- Integrated Variable Frequency Drive

- Integrated Heat Exchanger

- Super Premium Efficient IE4 Motor

Three-Stage Electroless Nickel Teflon Coated Blower

Used in the Food & Beverage industry, this maintenance-free, low noise blower replaces standard positive displacement technology which normally requires belt drives and extra silencing.

Features:

- Proprietary High-Efficiency Three Stage Blower Design

- Non-stick Electroless Nickel Teflon Coating

- External AC/DC Fan for maximum bearing cooling

- Premium Efficient Motor

DC Variable Speed Blower WIth Magnetic Drive

Used in the chemical industry, this blower features integrated motor cooling and isolated blower design which can retain process gas temperature.

Features:

- Custom Aluminum Blower Construction

- Magnetic Drive with Composite Barrier

- DC Motor

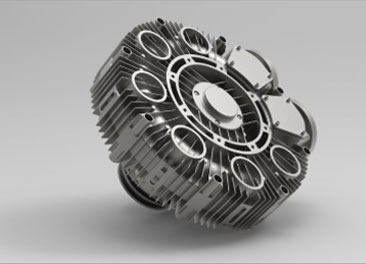

Two Stage Centrifugal Compressor

Used in the power generation industry, this compressor can boost up to 20PSIG with maintenance free operation.

Features:

- Custom Aluminum Housing

- Custom Titanium Impeller

- Optional Inter-stage Heat Exchanger

- Super Premium IE4 Motor

Two Stage Hybrid Regenerative Blower With Magnetic Drive

Used in the natural gas boosting industry, this blower is hermetically sealed for explosive gas streams and environments.

Features:

- Anodized Two Stage Blower Housing

- Magnetic Drive with Composite Barrier

- Internal Teflon Sealing for Maximum Performance

- Super Premium Efficient Motor

Two Stage Stainless Steel Blower With Magnetic Drive

Used in the electronics industry, this two-stage blower can withstand corrosive gases and high pressures up to 100PSIG.

Features:

- High Efficient Two Stage Design

- Stainless Steel Blower Construction

- Magnetic Drive with Composite Barrier

- Aluminum Heat Sinks for Optimal Cooling

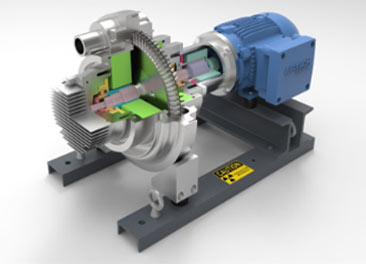

Belt Driven Regenerative Blower

Used in the Food & Beverage industry, this maintenance-free, low noise blower replaces standard positive displacement technology which normally requires oil-lubricated gearbox and extra silencing.

Features:

- Internal Teflon Sealing for Maximum Performance

- High Performance Ball Bearings

- Mounting for Belt Drive Operation

Stainless Steel Blower With Magnetic Drive

Used in the nuclear industry, this blower is hermetically sealed for radioactive gas streams and environments.

Features:

- Stainless Steel Blower Construction

- Embedded Depleted Uranium

- Magnetic Drive with Borosilicate Barrier

- Internal Teflon Sealing for Maximum Performance

DC Variable Speed Blower with Custom Filter

Used in the air sampling industry, this blower utilizes proprietary high speed technology to provide a wide operating range in a small footprint.

Features:

- Variable Speed DC Blower

- Custom Flow Meter & Filter Hybrid Design

- Custom Barbed Fittings for Easy System Integration

OUR CUSTOM ENGINEERING PROCESS

Airtech Vacuum Incorporated is an industry-leading manufacturer that is passionate about delivering the best vacuum and pump solutions to our customers. That’s why we fully understand that sometimes, the best solution is a custom one when it comes to vacuum and overpressure technology. Our custom engineering capabilities are well-regarded in the industry, and we can always build a new custom vacuum or pump system from scratch for your unique needs.

At Airtech, we have a stellar process for bringing the best custom engineering solutions to our customers. From the consultation to design to fabrication to product validation to assembling to testing phase, the priority of our product engineers is to listen intensively to your needs, and utilize our expertise and state of the art technology to custom build vacuums and pumps that fit right into your industrial operations. It is a promise that our product engineers will work relentlessly until we deliver a customized product that fully meets the requirements of the desired applications.

No project is too small or too large for us; whether you want to improve a small-scale operation in your production line or need multiple customized systems to support industrial operations in your international factories, Airtech deems it an honor to serve all our customers with an equal amount of dedication and commitment.

It’s time to trust our expertise and experience when you seek outstanding capabilities from custom pumps and vacuums. Contact us today and let our team assist you in securing stellar custom engineering solutions now.